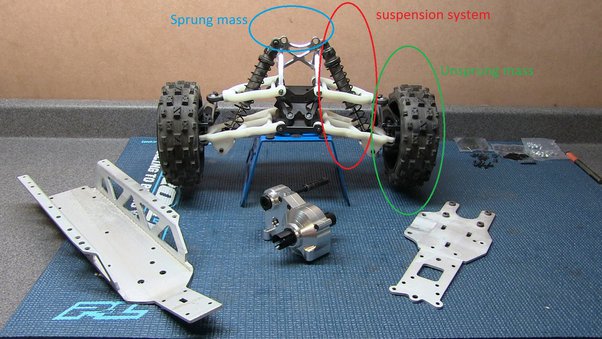

Baja ATVs (All Terrain Vehicles) are high-performance vehicles that navigate rough terrains and challenging environments.

These vehicles require specialized components, including the gearbox, to function optimally.

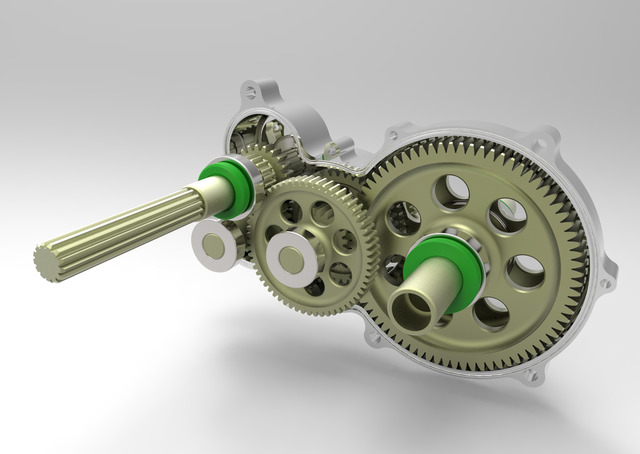

The gearbox is an important component that determines the power, speed, and efficiency of an ATV.

To design a custom gearbox for a Baja ATV, determine the required gear ratios, choose appropriate gear types, select materials, use CAD software to create detailed drawings and simulate performance, prototype and test the gearbox, and make any necessary modifications.

A custom gearbox can enhance the performance of your Baja ATV and make it more suited to your specific needs. This article outlines the steps in designing a custom gearbox for a Baja ATV.

Steps To Design A Custom Gearbox For Baja Atv

1. Determine The Gear Ratio

The first step in designing a custom Baja ATV gearbox is determining the gear ratio.

The gear ratio is the ratio between the number of teeth on the driving gear (the gear attached to the engine) and the driven gear (the gear attached to the wheels).

The gear ratio determines the torque and speed of the ATV. A lower gear ratio provides more torque, which is useful for climbing hills or navigating rough terrains, while a higher gear ratio provides more speed.

To determine the gear ratio, consider the terrain and the intended use of the ATV. If you plan to use the ATV for racing, opt for a higher gear ratio to increase speed.

However, choose a lower gear ratio for increased torque if you plan to use the ATV for rock crawling or mud bogging.

2. Choose The Gear Types

The second step is to choose the gear types for your custom gearbox. Three main types of gears are used in ATVs: spur gears, helical gears, and bevel gears.

Spur gears are the most common type of gear used in ATVs. They are inexpensive, simple, and easy to manufacture. However, they are also noisy and generate a lot of vibration.

Helical gears are more complex than spur gears but are quieter and generate less vibration. They are ideal for high-speed applications and are often used in racing ATVs.

Bevel gears are used to transfer power between shafts that are not parallel. They are more complex than spur and helical gears and require specialized machining.

3. Determine The Size And Number Of Teeth

The gears’ size and the number of teeth are critical factors in designing a custom gearbox.

The size of the gears determines the gear ratio, while the number of teeth determines the torque and speed of the ATV.

A larger gear will provide more torque, while a smaller gear will provide more speed.

The number of teeth on the gears should be chosen based on the gear ratio and the intended use of the ATV.

A higher number of teeth will provide more torque, while a lower number will provide more speed.

However, the number of teeth on the gears should be balanced to ensure the gearbox is not too heavy and is efficient.

4. Choose The Material

The material used to make the gears is an important consideration in the design of a custom gearbox.

The material should be strong, durable, and lightweight. The most common materials used in ATV gears are steel, aluminum, and titanium.

Steel is the most common material used in ATV gears. It is strong and durable but is also heavy.

Aluminum is lighter than steel but is not as strong. Titanium is the strongest and lightest material but is also the most expensive.

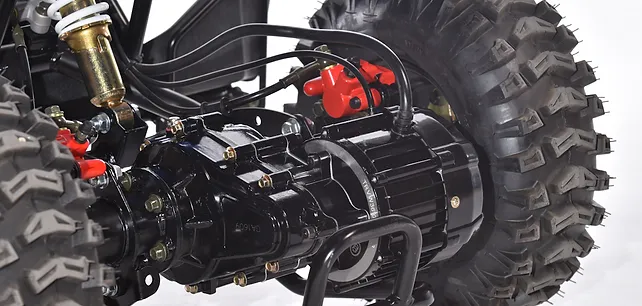

5. Design The Gearbox Housing

The gearbox housing is the outer casing that encloses the gears and other components of the gearbox.

The housing should be designed to withstand the forces generated by the gears and to protect the gears from damage.

The housing should be designed to be lightweight yet strong and durable.

The material used to make the housing should be able to withstand the forces generated by the gears and should be resistant to corrosion.

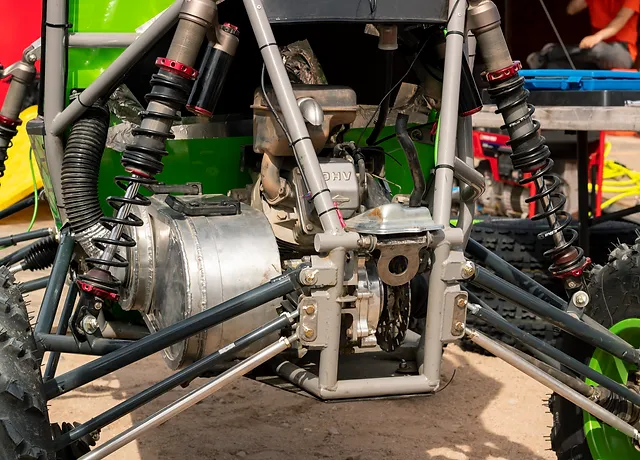

6. Test The Gearbox

Once the custom gearbox has been designed, testing it to ensure it performs as expected is important.

Testing the gearbox involves simulating the operating conditions of the ATV to evaluate the gearbox’s performance.

The gearbox can be tested using computer-aided design (CAD) software or by building a prototype and testing it on a dynamometer or the ATV.

The CAD software allows engineers to simulate the gearbox’s performance under various operating conditions, such as different speeds and loads.

Building a prototype of the custom gearbox and testing it on a dynamometer or the ATV is the most accurate way to test the gearbox’s performance.

Testing on a dynamometer involves connecting the gearbox to a machine that simulates the load and speed of the ATV.

It allows engineers to measure the gearbox’s torque, speed, and efficiency under various operating conditions.

Testing the gearbox on the ATV is the most accurate way to evaluate its performance.

It involves installing the custom gearbox on the ATV and testing it under real-world conditions.

It allows engineers to evaluate the gearbox’s performance in the intended application and make necessary adjustments.

Material Required For Custom Gearbox For Baja Atv

Designing a custom gearbox for a Baja ATV requires selecting appropriate materials to ensure the gearbox is strong, durable, and lightweight.

The materials used to make the gears, housing, and other gearbox components are critical to the overall performance of the ATV.

Below are some of the materials commonly used in the manufacture of custom gearboxes for Baja ATVs.

1. Steel

Steel is one of the most commonly used materials in manufacturing ATV gears.

It is strong, durable, and can withstand high loads and forces.

However, steel is also heavy, which can impact the overall weight of the ATV.

2. Aluminum

Aluminum is a lightweight material that is often used in the manufacture of ATV gearboxes.

It is not as strong as steel, but it is still strong enough to withstand the forces generated by the gears.

Aluminum is also corrosion-resistant, making it ideal for outdoor use.

3. Titanium

Titanium is the strongest and lightest material used to manufacture ATV gearboxes. It is more expensive than steel and aluminum but offers a superior strength-to-weight ratio. Titanium is also corrosion-resistant, making it ideal for outdoor use.

4. Carbon Fiber

Carbon fiber is a composite material made from carbon fibers and resin. It is lightweight and strong, making it an ideal material for ATV gearboxes. Carbon fiber is also corrosion-resistant and offers good heat resistance.

5. Plastics

Plastics are lightweight and can be molded into complex shapes, making them ideal for manufacturing gearbox housings.

Plastics are not as strong as metal, but they are still durable and can withstand the forces generated by the gears. They are also corrosion-resistant and offer good heat resistance.

When selecting materials for a custom gearbox for a Baja ATV, it is important to consider the intended use of the ATV, the forces generated by the gears, and the weight of the overall system.

Choosing the right materials will ensure the gearbox performs optimally and provides the desired performance characteristics.

What Are The Benefits Of A Custom Gearbox For A Baja ATV?

There are several benefits of a custom gearbox for a Baja ATV, including:

- Improved Performance: A custom gearbox can be designed to provide the desired performance characteristics such as speed, torque, and power. It can lead to better acceleration, higher top speeds, and improved off-road capabilities.

- Increased Reliability: Custom gearboxes are typically designed with higher-quality materials and precision manufacturing processes, which can increase the overall reliability of the gearbox. It can reduce the likelihood of breakdowns or other mechanical issues.

- Better Fuel Efficiency: A custom gearbox can be designed to provide the appropriate gear ratios for the intended use of the ATV, which can improve fuel efficiency. It can reduce the fuel the ATV consumes, resulting in cost savings over time.

- Longer Lifespan: Custom gearboxes are typically designed with high-quality materials and precision manufacturing processes, which can increase the overall lifespan of the gearbox. It can reduce the need for frequent repairs or replacements, resulting in cost savings over time.

- Customization: Custom gearboxes can be designed to meet specific requirements or preferences of the user. It can include the choice of gear ratios, gear type, materials used, and other features that can improve the overall performance of the ATV.

A custom gearbox can improve the overall performance, reliability, and lifespan of a Baja ATV, resulting in a more enjoyable off-road experience for the user.

Conclusion

Designing a custom gearbox for a Baja ATV involves several important steps, including determining the gear ratio, choosing the gear types, determining the size and number of teeth, selecting the material, designing the gearbox housing, and testing the gearbox.

Each of these steps is critical to ensuring that the custom gearbox performs optimally and meets the specific needs of the ATV.

By following these steps, you can design a custom gearbox that provides the desired performance characteristics, whether it is for racing, rock crawling, or other applications.

Always test the gearbox to ensure it performs as expected before installing it on the ATV.

Frequently Asked Questions

1. What Is A Custom Gearbox For A Baja ATV?

A custom gearbox for a Baja ATV is a transmission system designed and manufactured to meet the specific requirements of a Baja ATV. It is customized for performance characteristics like speed, torque, and power.

2. How Do I Choose The Right Type Of Gear For My Custom Gearbox For A Baja ATV?

The choice of gear type depends on the intended use of the gearbox and the level of speed reduction required.

Spur gears are the simplest and most common type of gear used in gearboxes.

Helical gears are quieter and more efficient than spur gears. Planetary gears are the most complex but can provide higher gear ratios.

3. What Is The Expected Lifespan Of A Custom Gearbox For A Baja ATV?

The expected lifespan of a custom gearbox for a Baja ATV depends on the design quality, materials used, and level of maintenance. With proper maintenance, a custom gearbox can last for many years.

4. Can I Install A Custom Gearbox On My Baja ATV Myself?

Installing a custom gearbox on a Baja ATV requires specialized knowledge and tools. It is recommended that a professional mechanic or an experienced ATV enthusiast do the installation.

5. How Much Does A Custom Gearbox For A Baja ATV Cost?

The cost of a custom gearbox for a Baja ATV varies depending on the complexity of the design, materials used, and level of customization required.

A basic custom gearbox can cost a few hundred dollars, while more complex designs can cost several thousand dollars.