Winches are great, and if you have one, you know how helpful this tool can be in situations where you cannot have help from another source.

However, there are many things that one has to consider when it comes to making use of this useful tool.

And sometimes these things may make the work harder than what it actually should be.

One of the most important things in a Winch is a solenoid which helps start the Winch.

But what if it stops working or does not initiate the Winch at all in the middle of a rush.

Thus, in such cases, people often end up not being able to get their work done.

And then this will also mean that you will not be able to complete your project or something similar in time.

But not anymore because there is a problem means there is a solution.

And solenoid not working is a serious problem, but with a reliable solution, you get your Winch wired and working without needing a solenoid.

Here Is How You Can Wire A Winch Without A Solenoid

Solenoid not working is a problem, but if you don’t know how to fix it, you are in misery.

Several techniques can be helpful when you don’t have a perfectly working solenoid.

Troubleshoot:

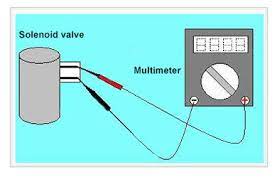

First, find out why your solenoid is not working and fix it by removing any wires from the power switch;

start by checking the wiring between the battery and the switch, check if any other components like

- Headlights

- Horns

- Mirrors

are switched on.

After this step, check if your fuse box is full or if there is an open circuit somewhere else;

Once this is done, unplug the car battery for some time and make sure you do not hear any sounds coming from your engine when you turn on the ignition.

Once all these steps are done, plug in the battery and wait for about 10-15 minutes,

After which try turning on the ignition again and check if your solenoid works fine or not.

If it works fine, replace the faulty component like

- Spark Plugs

- Headlights

- Radio

- Brake Lights, etc.

If it does not work, we need to move further with the wiring technique to solve this problem.

Complete Step by Step Process:

- After troubleshooting, the next step is to get your Winch free of any weight if it is carrying and put it into free spool mode. Same as when you put your car in neutral gear.

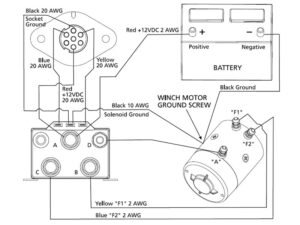

- Disconnect The battery from the positive terminal and let the ground wire keep connected with the battery. Label the three post wires with the motor as A f1 and f2 terminals.

- Now connect the jumper wire, which is the wire within this circuit. Run the cable from point A to F1 and then Connect it to the battery to F2. This will give a push to the Winch, and it will start in one direction at first (only if you plug all wires connection properly).

Now Repeat this process for the other side to make the winch work in another direction.

To make it winch in the opposite direction, you have to connect A and F2 posts with F1 alongside the battery.

After completing the process, if the motor works well in both directions.

The problem is not the solenoid. It may be the power switch or wiring causing the problem.

But this method is equally effective for problematic solenoids.

You can wire Winch if your solenoid is not working or bypassing the power properly.

What Is The Function Of Solenoids In Winch?

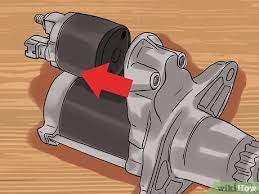

In the winch case, solenoids are used to activate a powerful motor and brake unit by giving a high current pulse in a few seconds,

which causes the motor to activate to rotate the drum or spool.

In the case of a power winch,

it uses an electric motor that turns the drum in the right direction.

That direction remains till the Winch pulls a heavy load.

If The load exceeds the motor’s torque capacity, then the spool starts rotating by increasing the tension of the rope attached to the spool.

In emergency rescue operations,

it is usually connected to a buzzer that gives warning alarms for pulling vehicles out of trouble or avoiding vehicle collisions with objects like walls, trees, etc.

In emergencies, when people need to be pulled out from cars.

It’s common practice to pull vehicles manually using cable wire.

Still, sometimes this can cause loss of human life due to many reasons,

like the insufficient amount of force pulling a person can cause back injury or fatality if proper measures are not taken while pulling them out from a car.

How Do You Change Solenoids?

As I mentioned earlier, there are some times when one has to replace a solenoid,

Because it may get broken due to misuse or wear and tear over time or maybe due to excess vibration during its use or operation.

So before starting any replacement procedure,

we need to follow the below-mentioned steps for a surety that we will be able to remove the old one correctly.

After replacing the new one, we will also connect the wires properly.

The wire would not short circuit with others which is must otherwise damage the solenoid coil and other components inside it.

Follow These Steps:

1. Check All Parts:

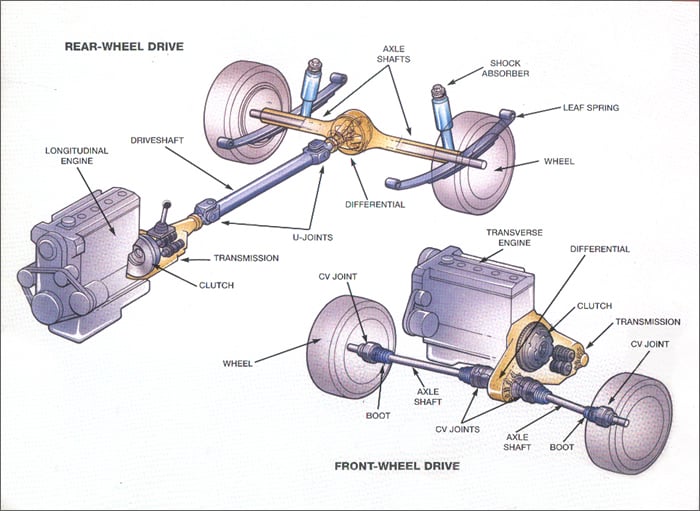

We have to check all other parts like the body,

- Brake system

- Wheel

- Gearbox, etc.

before removing the solenoid because this could also cause damage if they are broken.

Then only can we proceed with removing the old one from the vehicle.

2. Lose Bolts:

As the mounting points are fixed on different sides,

we have first to loosen the bolt and take off the locking nut,

detach wires attached to the solenoid with the help of a disconnector, then carefully pull the whole component off from the vehicle engine bay.

3. Check Connection:

Before attaching a new one, check that all connections are fine and fit in the correct position;

otherwise, damage may occur while re-attaching a new one.

So you have to ensure that these things are properly fitted before attaching them back.

4. Connect Bolts:

You can attach a new one by putting bolts through holes available at the front side of the assembly.

However, make sure you put enough pressure on bolts,

So they do not come out easily because we don’t want them to fall in the water when driving a vehicle in rainy conditions.

5. Final Finish:

Make sure you place your hands around all edges of the new solenoid while fitting so that if there is any place that gets scratched or worn.

Then there would be less chance of electrical shock

because sometimes moisture gets trapped inside or beneath components which might short circuit the electrical wiring system or damage some parts of the wiring harness or wire itself.

Safety Measure While Operating With Solenoid And Wiring Of Winches:

Before installing a new solenoid, always keep safety measures in mind as mentioned below:

Quality Material:

Use good quality materials for any mechanical component you use for installing it, like

- Quality Clamps

- Gaskets

- Better Screws, etc.

You can buy suitable electric motors and add oil thread online lock for compound more to smooth make the operation of strong electrical and motors sturdy in for different holding places tightly on vehicles engine.

Wear Safety Gloves:

Wear rubber gloves when working with wires of solenoids and battery etc.

Because electricity is involved, never forget to wear protective equipment and even insulated gloves and such items when operating the device with wires.

Get Help From Professionals:

Never Try to play with winches if you don’t know the exact wiring process or repairing it.

As we know, winches are used for pulling heavy objects, which makes it extremely harmful for persons who don’t know the exact steps.

One wrong wire connection can blow away your hand.

So be sure before you get your hands dirty with these tools.

Always call for professional assistance in any such case.

Don’t Panic In Any Situation:

Just in case, if something goes wrong in working conditions, panic won’t help anyone.

Rather try to correct the situation immediately without losing calmness as this will give a tough time to handle the situation better.

Last but not least is just turn off the main breaker switch before removing wires from any terminals.

As sometimes we may forget to disconnect them while moving some component around the vehicle engine.

So try to remember those few tips mentioned above before doing any job related to the automotive wiring system.

Conclusion:

Winches are not a playful object, and without guidance, this is not a tool to mess with.

If your solenoid suddenly stops working and you are in the middle of some heavy winching. You can use this process to wire the winch and back to work.

While handling this tool, don’t forget to turn off the main breaker switch. You can proceed with troubleshooting the problem.

And then you can wire the Winch without solenoid by following the guide (Be sure to go through all the steps).

Follow all safety measures and steps to get the wiring done and get back to work with a winch.

Also Read

- One-Way Motorcycle Adventure to Anchorage In 2023

- Painting ATV plastic with Krylon fusion? – Complete Guidances In 2023!

- What Happens If You Get Caught Riding An ATV On The Road? – Explore The Consequences!

- Suitable ATV for a Really Big Guy – Must Consider This Information

- ATV Accelerating Without Giving It Gas – Facts One Must Know In 2023!