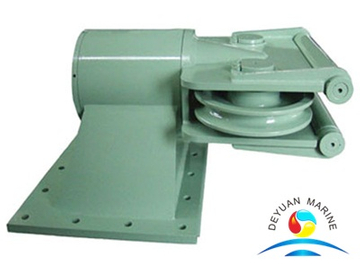

Roller fairleads are devices used to carry fiber optics across or along the direction of motion of the rolling structure.

They are associated with Fairleads serve as transitions between sections of cable, which may have significant mechanical resistance in some applications.

As the application may not need high transmission bandwidth but needs low crosstalk and other qualities.

Selecting a transition design with minimum dimensions and, therefore, the lowest possible loss is advisable.

Roller fairleads are used in steel wire cable winches because pull forces are high and need minimum effective bending radius of the fibers and high strain capability.

They also need a smooth transition between fiber segments to minimize coupling losses.

All modern design methods used to fabric roller fairleads consider stresses caused by shear and torsion and assume negligible axial loading of the fibers.

Axial loads can be limited by fixing fiber optic cables on top of each other or embedding them into cable jackets or substrates.

At the same time, sideloading is less severe since fibers do not have large dimension changes due to their elongation or contraction.

Things You Need To Know Before Installing Roller Fairleads

Always ensure you have sufficient light when working with ball joints.

They should be properly covered to not expose the interior parts to water or dust.

Also, keeping a supply of new rings will prevent metal parts from corrosion.

Also, try to replace worn-out rings at regular intervals to prevent possible damaging effects of mechanical damages and contact corrosion.

Installing a Roller Fairlead in your Cable Winch is simple, but only after following these basic rules.

Roller Fairlead Installation Process

Roller fairlead assembly is performed using hand-tightened ball joints.

Ball joints can be connected with small tools such as a torque wrench or screwdriver.

At the installation stage, the mating interfaces must be free of damage and without protrusions that could obstruct the passage of fibers.

The roller fairleads’ main application is their use in wire cable winches.

Installing them requires proper tools along with proper knowledge.

Here are steps on how you can install a roller fairlead into winches to save your steel cables.

Initiation:

- Remove excess insulation around the wire.

- Remove wire strands that would prevent wires from inserting into the rubber stopper.

- Gently slide a rolled section of rubber stopper over wires to guide wires through the ball joint.

- Adjust the tension on steel wires until there is little play between the rubber stopper and wire.

- Check if the roller fairlead has a full range of motion for installing wires without hitting the edges of the rubber stopper.

A Final Look At The Roller Fairlead Installation Process

The first thing you need to check while installing a roller fairlead is the operating angle of your winch and its alignment with the drum axis.

Rollers are installed at two positions, making their maximum horizontal run through 45 degrees and total angular play through 360 degrees.

When mounting rollers at the wrong position, it may reduce the operational life of rollers, breakage of steel cables, loss of performance, and increase the load on the gearbox.

Before using your winch, it is important to test its function by replacing any broken parts or cleaning grease off metal parts to ensure safe working conditions.

With properly functioning roller fairleads, you can increase the performance of your winch, reducing risks and risks of injuries while making operation easier.

On the same lines, all items should be stored away safely when not in use to avoid damaging them and losing functionality.

Benefits Of Roller Fairlead

- Protects cables from breaking due to collision.

- Provides ease of movement for drum due to higher rolling force.

- Decreases wear and tear of cable during transport.

- Eliminates tangling of cable.

Types Of Roller Fairlead

- Manual Roller Fairlead

- Remote controlled Roller Fairlead

- Locking Roller Fairlead

- Snap Hook Roller Fairlead

- Cam Buckle Roller Fairlead

- Jaw Clamp Roller Fairlead

- Swivel Hook Roller Fairlead

1. Manual Roller Fairlead

Manual roller fairleads have multiple layers of strands that separate inside a case, protecting rollers from sudden jerks or sharp collisions.

This type of fair lead allows manual winding or release of the drum without causing damage to wire rope.

It also prevents tight winding that reduces rope slippage during normal operations.

It has small friction resistance between strands that keeps drums steady while running.

Ensuring the proper engagement of sheaves with rope and no slip-shifting during slippery conditions.

2. Remote Control Roller Fairlead

Remote-controlled roller fairleads allow users to pull on rope manually or let rope retract to operate the winch remotely.

These types of fairleads prevent unwanted tensioning or disengagement of sheaves with a rope.

They could damage ropes and pulleys and extend the drum’s service life.

They also ensure better drum handling due to smoother pull-out action.

The lower frictional resistance between strands, reduced chances of slip-shifting, and increased reliability.

3. Locking Roller Fairlead

Locking roller fairleads lock drums against displacement by the weight of loaded wire rope, preventing slack take-up.

During fast hoisting operations and saving money on costly rewinding operations.

They also ensure stable lifting, loading, and unloading operations by locking drums in place when necessary.

They are equipped with low friction bearing material that ensures the smooth movement of drums.

While protecting the entire mechanism from harsh operating conditions.

4. Snap Hook Roller Fairlead

Snap hook roller fairleads provide ease of quick hoisting by allowing easy take-up of loaded rope, quick replacement of faulty hooks, and reducing maintenance time.

By ensuring free flow of wire rope through the mechanism.

They prevent uneven loads from putting extra pressure on components, allowing better reliability and durability.

5. Cam Buckle Roller Fairlead

Cam buckle roller fairleads offer an easy solution for quickly replacing sheaves with large capacity.

Due to the increased ability to accept large sizes of hooks and greater clamping range.

These fairleads provide faster load exchange than traditional cam or clevis type designs.

They also eliminate misalignment problems associated with improper fitting sheaves and guarantee positive alignment with their safety mechanisms.

6. Jaw Clamp Roller Fairlead

Jaw clamp roller fairleads feature one jaw capable of expanding for accommodating different sized ropes and work as sheave holders when ropes are not used.

They prevent abrasion, uncontrolled bending, shock loading and elongation, wear, corrosion.

Rough operation that improve performance and enhance other components’ working life.

They can be fitted to virtually any lift device or suspended crane system.

7. Swivel Hook Roller Fairlead

Swivel hook roller fairleads have integrated rollers for swiveling movements combined with standard tension pulleys.

It helps to avoid stressing the machine structure when a drum is stationary and use friction in motion for automatic positioning.

They allow rotation in either direction without adding a structural modification to existing structures.

They eliminate snag problems associated with alternative solutions.

These devices are applicable for operations where conventional winch systems are not useable due to restriction of working space or elevated locations.

Conclusion

Roller fairleads are quite simple devices that can greatly improve the safety and productivity of various heavy equipment like forklifts, mobile cranes, winches, etc.

These products reduce stress on components and increase efficiency, making the machine highly economical and long-lasting.

However, it would help if you considered all pros and cons of using them before investing in them.

When you know how they work, the advantages will become more apparent.

Video Guide

Also Read

- One-Way Motorcycle Adventure to Anchorage In 2023

- Painting ATV plastic with Krylon fusion? – Complete Guidances In 2023!

- What Happens If You Get Caught Riding An ATV On The Road? – Explore The Consequences!

- Suitable ATV for a Really Big Guy – Must Consider This Information

- ATV Accelerating Without Giving It Gas – Facts One Must Know In 2023!