Dive into the world of maritime machinery with our comprehensive guide on tugger winches. Understand their purpose, types, and differences from other winches.

When it comes to handling hefty loads, maritime operations rely on a powerful tool known as the tugger winch.

This versatile piece of equipment, often found on offshore vessels and oil rigs, plays a pivotal role in various heavy-duty tasks, from shifting equipment to maintaining tension in mooring lines.

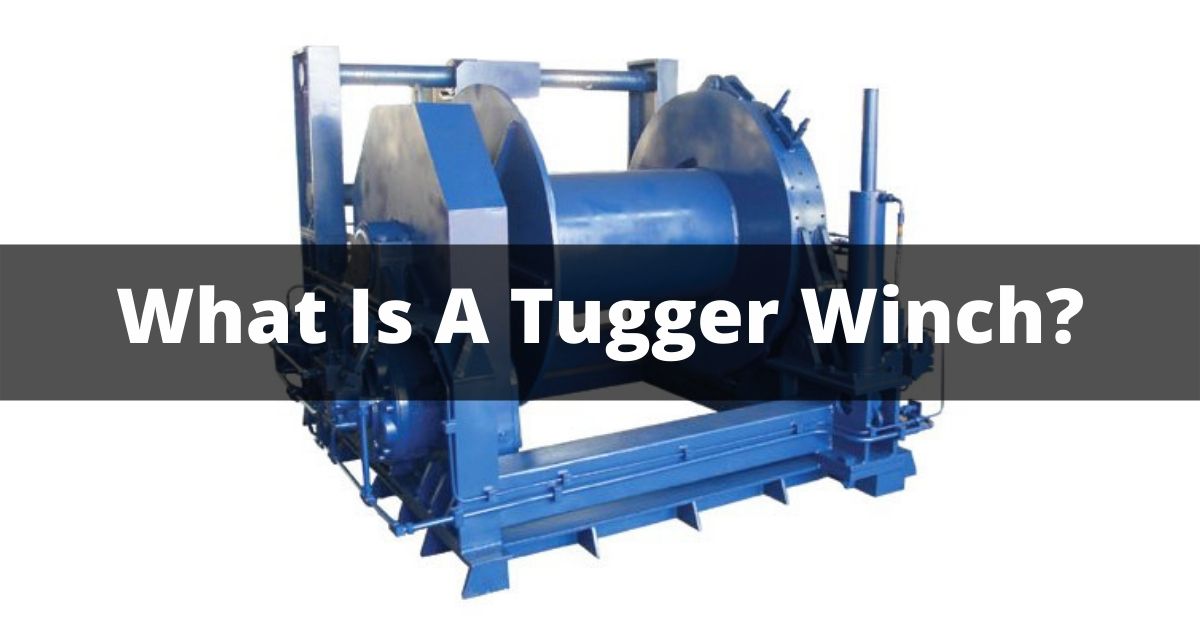

A tugger winch is a mechanical device, essentially a spool wound with rope or wire, that is powered by either an electric or hydraulic motor.

What sets it apart is its durability and adaptability in the face of demanding maritime operations.

What Is A Tugger Winch Used For?

Maritime operations require the lifting, pulling, and positioning of substantial weights, and that’s where the tugger winch shines.

From securing ships at port to anchor handling, the tugger winch facilitates a broad range of applications.

One of its primary uses is in mooring operations, where it maintains the tension in mooring lines and keeps the ship positioned correctly.

In offshore industries, these winches are integral to material handling and deck operations, especially in inclement weather.

Types Of Tugger Winch

Tugger winches are classified mainly by their power source: hydraulic or electric.

Hydraulic tugger winches are praised for their robustness and reliability, often preferred in heavy industrial settings. They make use of fluid power to generate force and motion.

Electric tugger winches, on the other hand, operate through an electric motor and a variable-frequency drive.

These winches are known for their efficiency and precision, making them a popular choice for smaller vessels and more intricate operations.

Benefits of Tugger Winch

Investing in a tugger winch can significantly streamline maritime operations, bringing a wealth of benefits to the table.

First and foremost, they excel at handling heavy loads, providing an effective solution for lifting, pulling, and maintaining tension in various applications – from securing ships at port to assisting in deck operations.

With the choice of either a hydraulic or electric motor, tugger winches offer flexibility in catering to specific operational needs.

The hydraulic models are renowned for their robustness and reliability, ideally suited for heavy-duty industrial settings.

Meanwhile, electric models are praised for their efficiency and precision, perfect for smaller vessels and intricate operations.

Moreover, tugger winches are designed to withstand tough maritime conditions, making them a reliable ally in inclement weather.

The fact that they can operate under such challenging circumstances not only boosts operational efficiency but also contributes to workplace safety.

Features of Tugger Winch

Tugger winches boast a range of features designed to make maritime operations smoother and safer. The core component is a strong, durable drum or spool, around which the rope or wire is wound.

The drum is powered by a motor, which can be either hydraulic or electric, depending on the specific model and application.

Some tugger winches feature a variable-frequency drive, allowing for precise control over the speed and torque of the winch. This is especially useful in operations where a high degree of accuracy is required.

The winches are also equipped with a braking system to secure the load when the winch is not in operation. This is a crucial safety feature that prevents accidental slippage or movement of the load.

Depending on the model, some tugger winches may also have features like a tension monitoring system to maintain the correct tension in the line, and remote control capabilities for ease of operation.

In a nutshell, the features of a tugger winch are designed to enhance operational efficiency, ensure safety, and offer flexibility across a wide range of maritime applications.

What is the difference between Tugger Winch and Anchor Windlass?

While both tugger winches and anchor windlasses are vital maritime tools, they serve distinct purposes. An anchor windlass, as the name suggests, is primarily used to lift and lower the anchor, while a tugger winch’s applications are broader, including lifting, pulling, and maintaining tension in various operations.

What is the difference between Tugger Winch and Cargo winch?

A cargo winch, another key player in maritime operations, is specifically designed to handle cargo operations on ships. While a tugger winch can also be used for similar purposes, its application extends beyond cargo operations.

What is The Tugger Winch Function?

The tugger winch’s central function revolves around manipulating heavy loads. This workhorse of the maritime industry provides the muscle to lift, pull, or position weights, utilizing its robust construction and power source. It also plays a pivotal role in maintaining tension, ensuring safe and secure operations at sea.

Conclusion

In essence, a tugger winch is a maritime MVP, offering versatility, power, and reliability. Whether it’s mooring operations or cargo handling, tugger winches have become indispensable in today’s maritime industry.

Remember, safety is paramount, and proper training and understanding of these machines are crucial for all operators. Here’s to smoother sailing and efficient operations with the tugger winch!

FAQs:

What powers a tugger winch?

Tugger winches are powered either by an electric or hydraulic motor.

Are tugger winches safe to use?

Yes, but proper training and understanding of these machines are crucial for safe operations.

How does a tugger winch work?

A tugger winch uses power from an electric or hydraulic motor to wind a spool, pulling or lifting heavy loads.

Can a tugger winch be used in bad weather?

Yes, they are designed to withstand tough maritime conditions, but safety protocols must always be followed.

Video Guide

Also Read

- One-Way Motorcycle Adventure to Anchorage In 2023

- Painting ATV plastic with Krylon fusion? – Complete Guidances In 2023!

- What Happens If You Get Caught Riding An ATV On The Road? – Explore The Consequences!

- Suitable ATV for a Really Big Guy – Must Consider This Information

- ATV Accelerating Without Giving It Gas – Facts One Must Know In 2023!

External Resources: