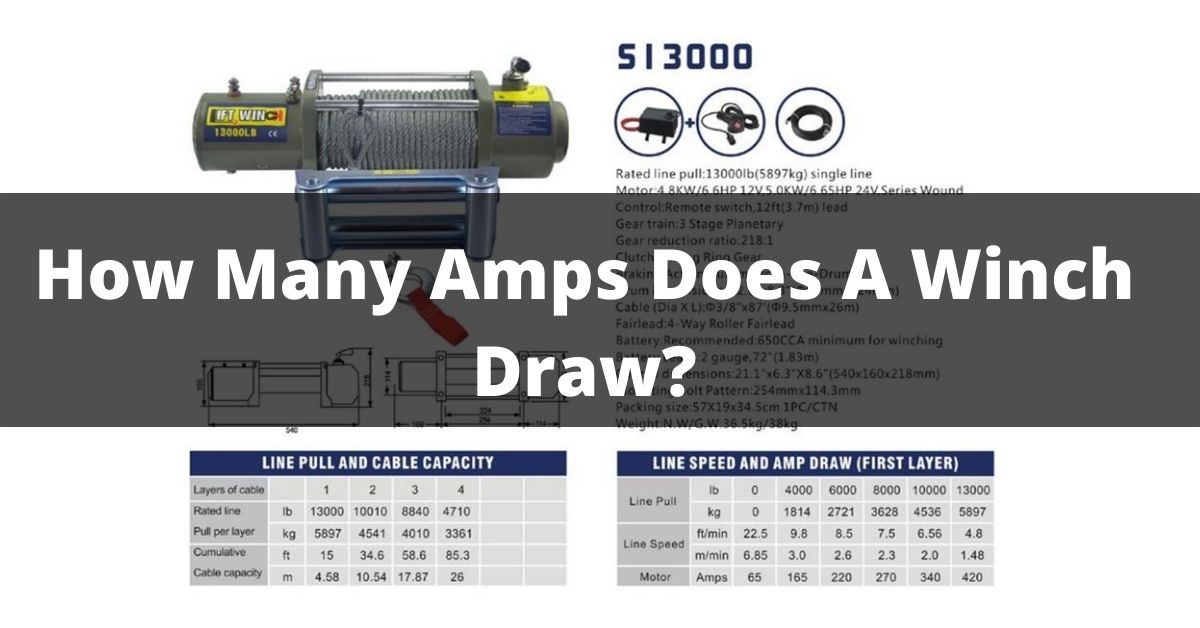

The winch draws amperes according to performance it gives in a specific period.

It can draw anywhere between 1 amp to 50 amps or maybe higher than the one requested by you.

Before that, there were many variable things such as quality of the wire, engine load, drum speed, brake cable friction, etc.

The main factor which can affect the consumption of amp is that of load, and this should be maximum for its operation.

Therefore, a heavy-duty winch with very low rpm but high horsepower will consume much more amp than one with high RPMs but lower horsepower.

If we calculate how many amps a Winch Hoist draws on different machines, we can have an idea about what size machine.

you will need to move the load around, and this calculation will work even when the machines come with different hp ratings.

There are also factors such as

- Tire pressure

- Lubrication level

- Fuel type

whether you want to drive the machine manually or take it out from underwater, etc.

Other important variables are the condition of the oil pump, tension control, etc.

5 Aspects To Give A Better Idea About The Consumption Of Amps By Winch

1. Horse Power

How many horses do you want your winch to draw?

If it is 200 hp, then you can buy any motorized winch with 10 amps capacity, 20 hp machine will require 2 amps per 100 ft while 3 hp machine will require 4 amps per 100 ft.

So according to these calculations, if you need 50 ft wire, then your wire requirement will be 500 ft4 amps=2 KVA & if you need 20 ft wire, then your wire requirement will be 1000 ft4 amps=4 KVA.

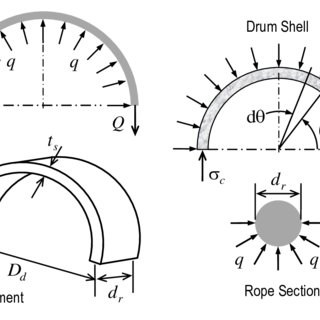

2. Volume And Number Of Drum

If you want to know how many amps a winch draws, then the first thing you should do is find out the volume of the drum.

which is not easy because in most cases, manufacturers have changed their sizes, and therefore their actual volumes are not the same as before.

For example, some old steel reels were 12 feet in diameter while others were 8 feet.

There were various reasons behind such change, so there are various types of drums that can be found on the market today.

One such popular type is the ladder line drum, which has a 1-inch height for the top section & a 3-inch height for the bottom section.

It helps ensure less contact between wires and drum & at the same time,

its cylindrical design makes it possible to load a maximum amount of rope without binding or pinching of rope between drum & floor & sidewall.

So this gives a clear idea about the volume of drum required for each horsepower,

And now we can compare our drum volume with the motor’s output capacity and check whether our drum size matches our requirements.

You should also consider the number of drums that can be used together.

Because it may cause conflict in the loading process if they are loaded in different manners.

3. Operating Current

The next factor affecting amps is operating current,

which means the current required to operate a motor at rated RPM or voltage applied to the motor for the start-up process.

This depends on what motor you are using

- Standard alternator

- AC generator

- 3 phase induction motor, etc

For all these motors, we will give them specific ratings, but these ratings can vary according to horsepower rating and running speed.

4. Duty Cycle

Duty cycle or running time means the percentage of time when a motor runs under load or continuous operation,

which again varies with different types of motors.

They may have a low duty cycle below 40%, while others may have a 90% duty cycle which means a continuous operation for more than 24 hours.

At the same time, it also depends on the type of material you are working with like nylon ropes require high-speed rotation.

So it is recommended to run motors on the high duty cycle and temperature rise during start-up period which will reduce the motor’s life.

But running on a low duty cycle is not advisable because you can’t afford frequent shutdown periods due to cost factors.

5. Limitation Of Methodology

Since all of the components used in calculation have certain characteristics, certain conclusions may not apply to a few Winches.

Also, the load applied may change with a change in altitude or climate conditions.

So that some factors can vary depending on geographical location and ambient conditions.

In addition, if a vehicle operator presses the accelerator at full throttle, then obviously, consumption of amps will be high as it would require maximum torque output from engine and motor.

which is beyond the limits of those vehicles.

However, various speed governors are present in modern vehicles that automatically reduce torque output depending on road conditions.

This means that actual torque output can be significantly less than the rated value.

So, that fewer amps would be consumed by a vehicle depending on driving conditions.

Conclusion

Generally, the most popular 1-tonne capacity winches would consume a maximum of 10 amps per cycle.

And approximately 400 amps per hour when driven manually.

Still, underwater conditions, even at top-end models, would only draw about 300 amps.

It is easily manageable by any car batteries and their controllers.

So this article should help you understand what exactly your winch consumes during each stroke.

And how many amps it uses when winching in dry conditions and water or underwater conditions.

Also that i wrote an article for you about a Winch And Its Types and it will be helpful for you.

Video Guide

Also Read

- One-Way Motorcycle Adventure to Anchorage In 2023

- Painting ATV plastic with Krylon fusion? – Complete Guidances In 2023!

- What Happens If You Get Caught Riding An ATV On The Road? – Explore The Consequences!

- Suitable ATV for a Really Big Guy – Must Consider This Information

- ATV Accelerating Without Giving It Gas – Facts One Must Know In 2023!