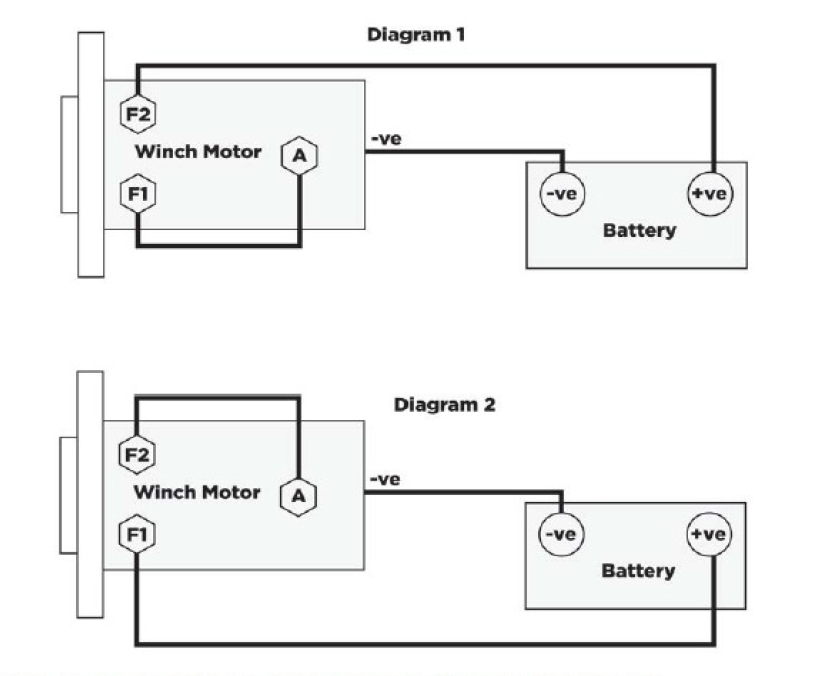

A winch moves in and out in directions, which the tachometer can monitor on the side of the motor.

To test a winch solenoid a wire is connected solenoid of the winch with the battery and will try to move from its set position when power is applied.

The charging power moving from battery to solenoid is 12 volt, and if it is malfunctioning, it will make a clunk sound. This will continue for a few seconds then stop as the current running through the solenoid drops below 3ma.

Complete Procedure:

Attach wires from motor and battery to the solenoid Run the motor for 1-2 seconds after connection Turn off motor.

Check voltage across solenoid after 15 seconds When the voltage falls below 3ma stop the motor.

Now, there should be no sound coming from the solenoid, but this should be kept in mind .

If any fault arises during testing, they must be diagnosed first, only then if required further action can be taken.

If you have done this properly, your machine will not show any faults in operation, and it will operate smoothly for years to come.

The clunk sound should also stop now, as the current flowing through the solenoid has stopped.

If you want to check whether your machine is working fine or not, just disconnect the solenoid from the battery and connect .

Check again whether there is any clunk sound; if yes, what could be the problem?

Possible Reasons For Solenoid Malfunctioning:

There are several reasons why the solenoid of the winch may have stopped working.

Here are some reasons for such problems:

1. Solenoid In Contact With Ground:

Solenoid always comes in contact with earth while switching off.

sometimes, a machine starts its movement by accidentally pressing the start button while still connecting wire with battery.

No proper switch has been installed on the circuit board.

When the wire touches the contact point on the switch – its body gets broken by friction between the metal part of the contact point and the wiring part of the wire.

Now, this causes trouble for all other electronics parts connected to that circuit board like a relay, drive, etc. So as a result, your machine won’t work anymore.

If you feel your machine isn’t working fine even after making the above checks, go to home depot and get an experienced technician to look into this issue. Otherwise, it may also cause fire accidents if left unattended.

2. Rusted Wires:

The rusted wire is another reason your solenoid may not be working because the rusty wire gets more difficulty in carrying electric current than good quality wire.

When rusty wire touches the metal part of the contact point, it burns out, which may damage all other electronic parts connected to it.

As a result, you will also face the same problem as others mentioned above; it is best to change the entire wiring system for safety purposes.

3. No proper Charge:

Solenoids carry charge from the battery to move the winching process, but if the charge is not in a proper flow or less than 12-volt, solenoids may get damaged or may not initiate the winch.

Check your charge regularly or else call an experienced technician for help.

To test a winch solenoids can be tested whether they are working or not with the help of this method:

Test A Winch solenoid:

Cutting open winch motor terminals by applying a breaker with a voltage between 18-22 volts ( 12-14V);

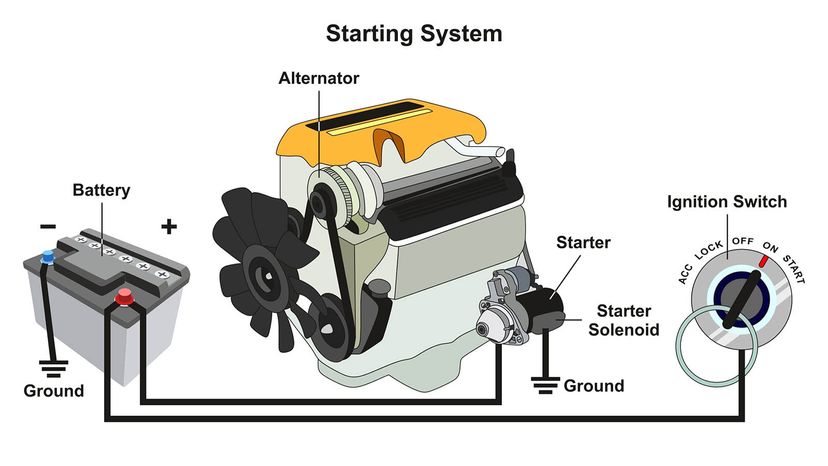

Now test whether there is enough current coming from the battery when the engine is running with an alternator connected with the motor. If yes, then there is no problem, else replace solenoid for safety purposes.

Again, testing charges should be done before making these changes as by doing this, we may have lost control over this matter and thus resulting in unwanted problems.

Get rid of such issues before making changes to any electronic device.

Bench Test Of A Solenoid Winch:

A bench test is a simple testing method to check whether an object is working or not. For bench testing the operation of Winch solenoids.

You have to check several factors which directly or indirectly affect the performance of Solenoids.

If you troubleshot every aspect of the winch, but you should follow precautions before you put your hands on the winch.

If you are not a professional, avoid the whole process and call an expert to deal with the issue.

Winches are not a toy to play with, they can cause serious damage to themselves and its surrounding. So be careful before trying any tips or tricks.

Summary:

Above was a brief tutorial on some basic reasons for non-functioning winch solenoids and other related information.

Remember always to use electrical equipment carefully & properly as without this we can lose everything around us, including our life.

These are a few reasons which can make your solenoid working difficult or even retard the process. So you just need to do a thorough checkup on this issue before trying any troubleshooting tricks on your own.

The given points above can be considered basic knowledge of how these solenoids work & what kind of problems affect their efficiency.

Video Guide:

Also Read

- One-Way Motorcycle Adventure to Anchorage In 2023

- Painting ATV plastic with Krylon fusion? – Complete Guidances In 2023!

- What Happens If You Get Caught Riding An ATV On The Road? – Explore The Consequences!

- Suitable ATV for a Really Big Guy – Must Consider This Information

- ATV Accelerating Without Giving It Gas – Facts One Must Know In 2023!